To develop production involves making changes. As production grows, new needs arise, such as the installation of a hygienic ATEX-rated diaphragm pump. That's exactly what the Swedish distillery Stockholms Bränneri did when their production methods needed streamlining, and they contacted Tapflo.

The process was initiated over two years ago when they realized that it was no longer sustainable to move liquids using gravity and a pallet lifter between their stationary tanks – production had started to grow. A former employee with experience in brewing had positive experiences with Tapflo in other contexts and initiated contact.

Pump selection with special requirements

Marcus Böhme, Head of Production at Stockholms Bränneri, explains that the pump needed to meet specific requirements for functioning within the production environment, its design, and characteristics. Therefore, the pump was expected to:

- Be easy to clean.

- Be easy to maintain.

- Be designed according to ATEX standards (for explosive environments).

- Be user-friendly.

- Be capable of pumping liquids with varying viscosities.

- Be equipped with a 1.5" TC coupling to match the other couplings in production

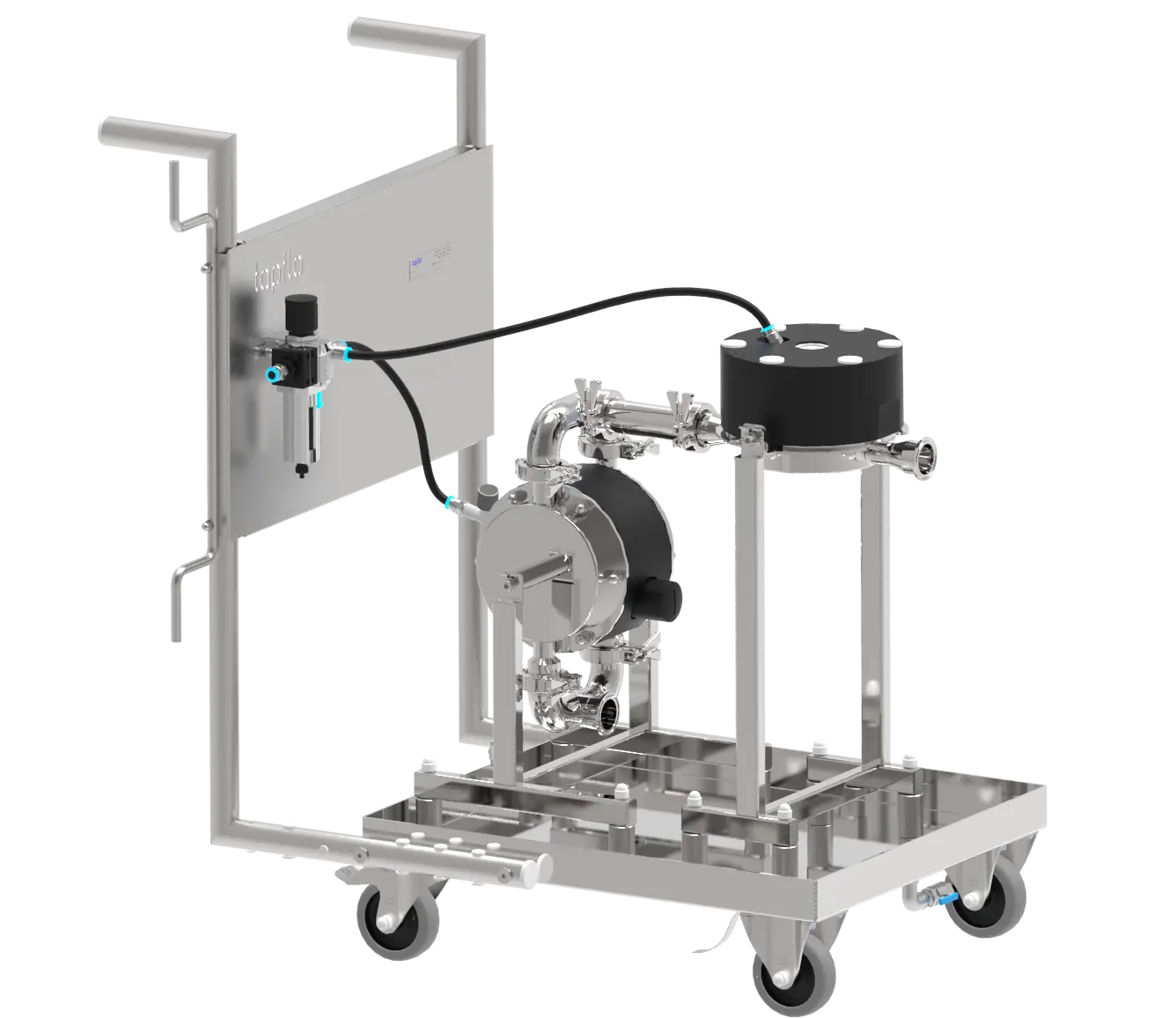

In agreement with Tapflo, the result was a T125 pump with a pulsation dampener, mounted on a trolley, fully adapted to explosive environments.

"It does everything we have wanted it to do so far"

Choosing a hygienic diaphragm pump in alcohol production contributes to high-quality production, provided it is used correctly. When selecting a pump for food production, it is essential to consider the pump's hygienic properties to prevent bacterial growth in the product. The pump's characteristics can be crucial in meeting production requirements:

- The conductive black center block ensures that no electrical charges occur in the pump.

- The design allows the operator to disassemble the pump for regular maintenance.

- The smooth surface prevents dirt from adhering to irregularities and facilitates cleaning.

- It is capable of pumping fluids at all stages of the production process.

To further enhance production, a pulsation dampener can smooth out pulsations, reduce pipe vibrations, and minimize noise, thereby creating a more pleasant working environment. Mounting the pump on a trolley makes it flexible and suitable for various purposes within the process.

Marcus says that the pump is used to transfer various types of liquids every day. Some of the applications at Stockholms Bränneri include transferring 96% organic ethanol from a storage tank to a distillation kettle, transferring finished products from a blending tank to a storage tank, and pumping fruit juice from an IBC tank.

"It does everything we have wanted it to do so far. It's easy and quick to use, handle, and clean, allowing for seamless switching between different liquids," says Marcus.

Since its inception in 2015, Stockholms Bränneri has been producing gin, aperitifs, aquavit, and pre-bottled cocktails, among others, all of which are compatible with Tapflo's hygienic diaphragm pumps.

Are you curious to learn more about hygienic diaphragm pumps or other flow solutions? Contact us for more information.