Technical data

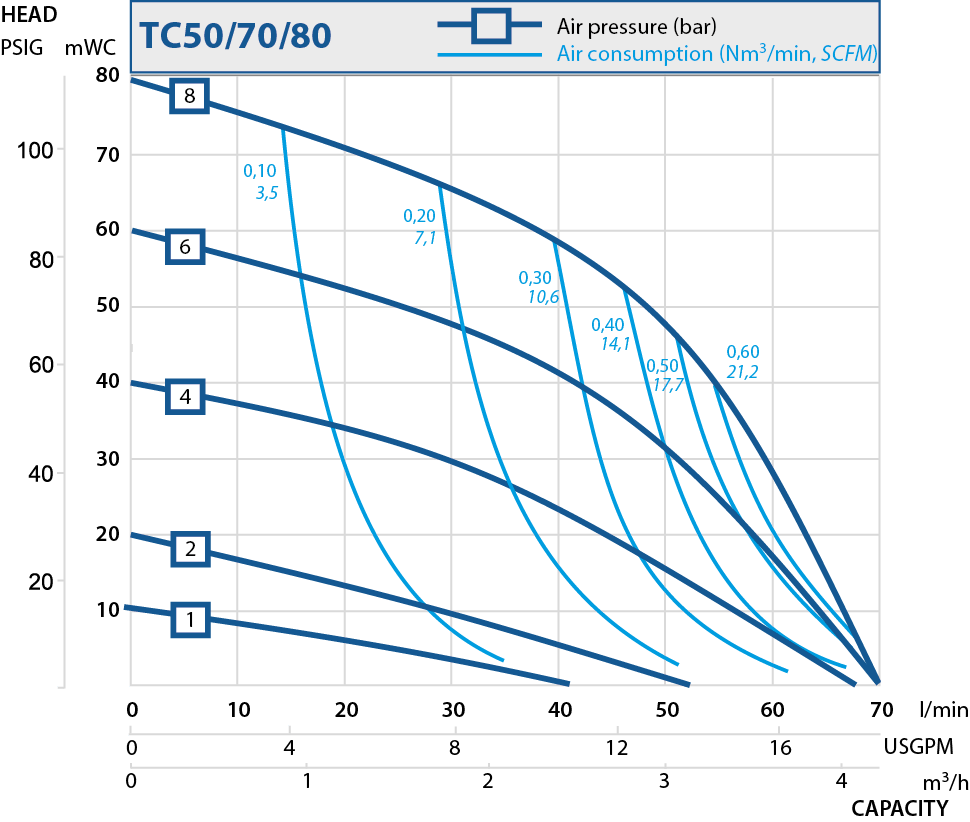

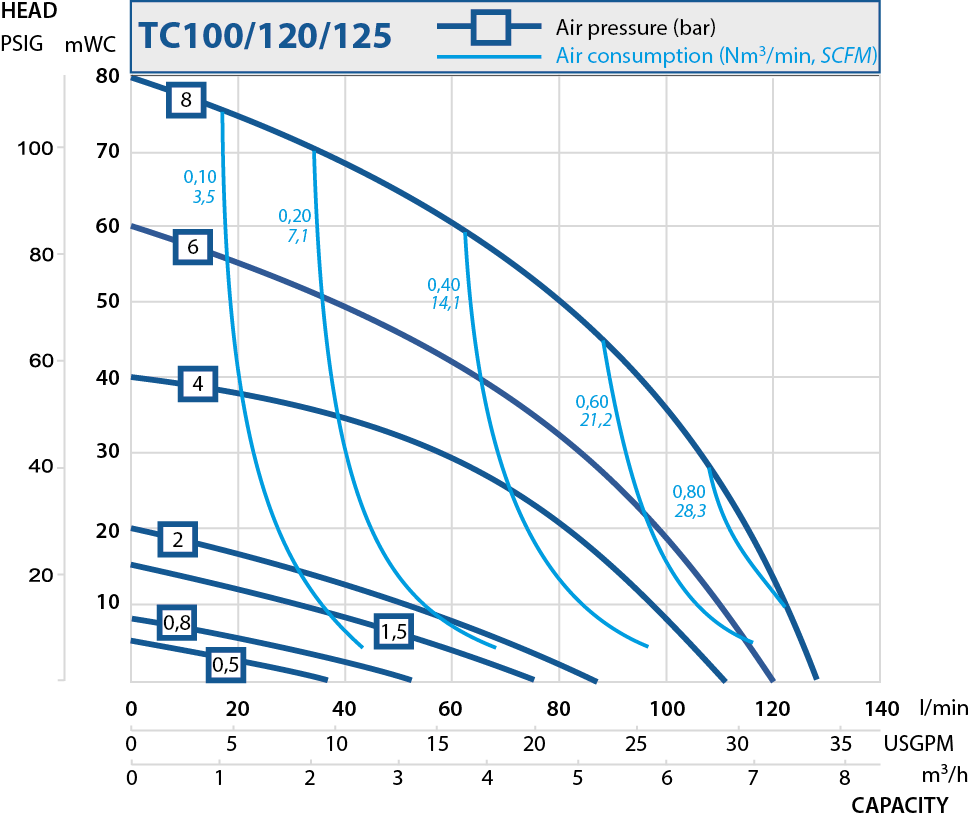

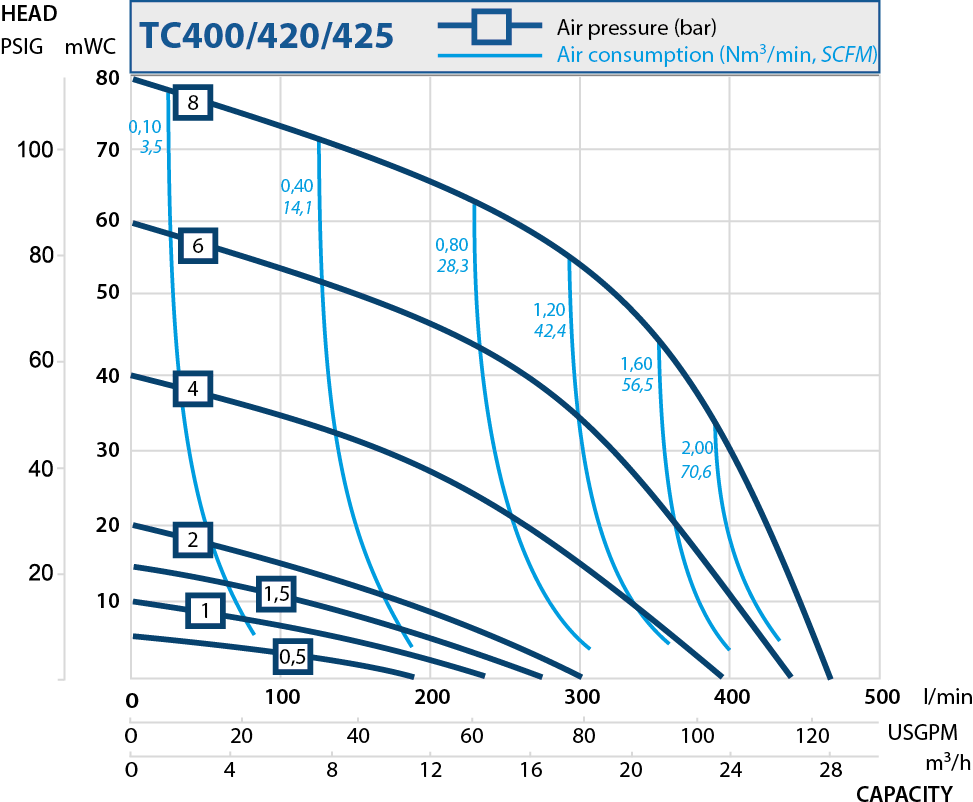

| Model | Max capacity (l/min) |

Connections BSP inv. |

| TC50/70/80 | 60 | 1/2" |

| TC100/120/125 | 125 | 1" |

| TC200/220/225 | 330 | 1 1/2" |

| TC400/420/425 | 570 | 2" |

TC Intelligent pumps are fitted with ingenious LEAP® technology developed by Tapflo.

LEAP® or ‘Low Energy Air Pump’ is a patented technology used in AODD pumps to reduce the minimum operating air pressure by reducing internal losses and friction found in conventional AODD pumps.

LEAP uses a unique indirect system to detect the position of the diaphragm shaft controlling the diaphragm movement automatically.

Features & Benefits

- Available in Plastic, Metal and Sanitary series AODD pumps

- Retrofit

- Batch Dispensing

- Improved Lifespan

- Dry Running

- Noise Reduction

- Electrical feedback

- Improved Maintenance

- Control Simplification

- Dead Heading