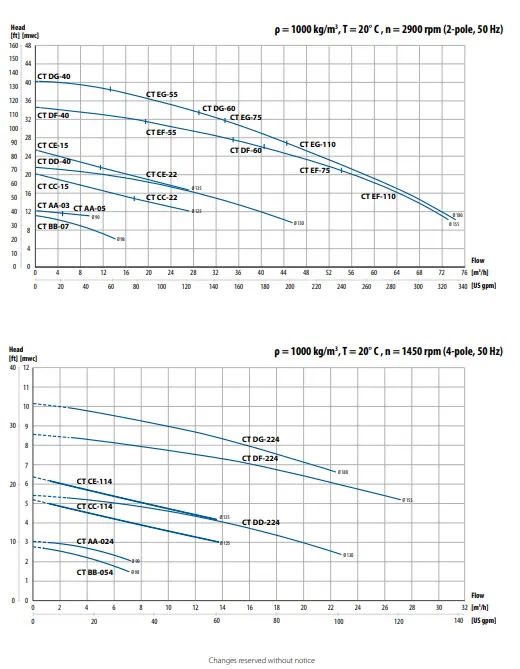

Technical data

| Model | Motor power KW |

IEC Motor size |

| CTH AA-03 | 0.37 | 71 |

| CTH AA-05 | 0.55 | 71 |

| CTH BB-07 | 0.75 | 80 |

| CTH CC-15 | 1.5 | 90 |

| CTH CC-22 | 2.2 | 90 |

| CTH CE-22 | 2.2 | 90 |

| CTH DD-40 | 4.0 | 112 |

| CTH DF-40 | 4.0 | 112 |

| CTH EF-55 | 5.5 | 132 |

| CTH EG-55 | 5.5 | 132 |

| CTH EF-75 | 7.5 | 132 |

| CTH EG-75 | 7.5 | 132 |

| CTH AA-024 | 0.25 | 71 |

| CTH BB-054 | 0.55 | 80 |

| CTH CC-114 | 1.1 | 90 |

| CTH CE-114 | 1.1 | 90 |

| CTH DD-224 | 2.2 | 100 |

| CTH DF-224 | 2.2 | 100 |

| CTH DG-224 | 2.2 | 100 |

The CT pumps are open or semi open impeller single stage centrifugal pumps. They are manufactured in high finish and mechanically strong material - AISI 316L stainless steel. The pump range meets the demands from a variety of today’s industries. Having said that, CT is still available at a very appealing price level.

The hygienic series CTH is supplied with electro polished pump casing and internals. This series is dedicated for hygienic duties in food, beverage and pharmaceutical industries, where clean and drain-ability are important factors.

Features & Benefits

- Simple design

- Few parts

- Open impeller

- High grade materials

- Multiple options

- Compact design

- High capacity

- Competitive price

- Low maintenance cost

- Solids handling

- Good quality/cost ratio

- Wide range of applications

Typical APPLICATIONS

Chemical & pharma

Transport of chemicals from storage tanks, containers and baths, for example in degreasing. Handling of waste products.

Food & beverage

Transfer of various ingredients and products like edible oil, flavor, alcohol, dairy products and juice. With heating jacket version there are further possibilities like pumping margarine and chocolate. There are also many auxiliary applications like transfer of cleaning liquids and water.