Technical data

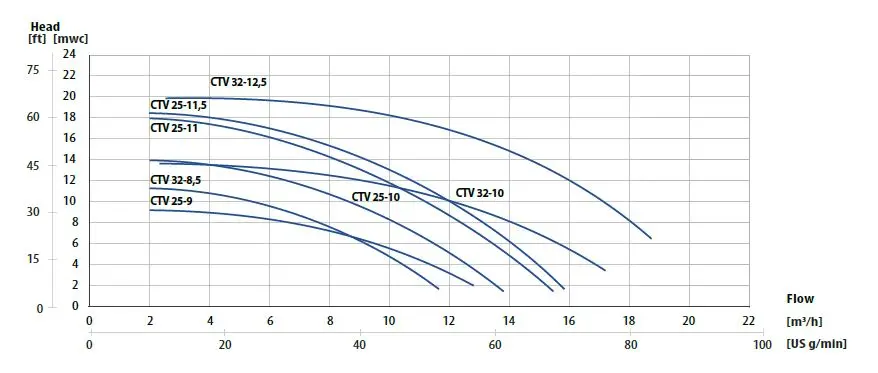

| Model | Max capacity (m3/h) | Motor power , kW | Outlet dimension (male BSP) |

| CTV 25-9 PP & PVDF | 12 | 0.55 | 1" |

| CTV 25-10 PP & PVDF | 14 | 0.75 | 1" |

| CTV 25-11 PP & PVDF | 15.5 | 1.1 | 1" |

| CTV 25-11.5 PP & PVDF | 16 | 1.5 | 1" |

| CTV 32-8.5 PP & PVDF | 13 | 1.1 | 1¼” |

| CTV 32-10 PP & PVDF | 17 | 1.5 | 1¼” |

| CTV 32-12.5 PP & PVDF | 19 | 2.2 | 1¼” |

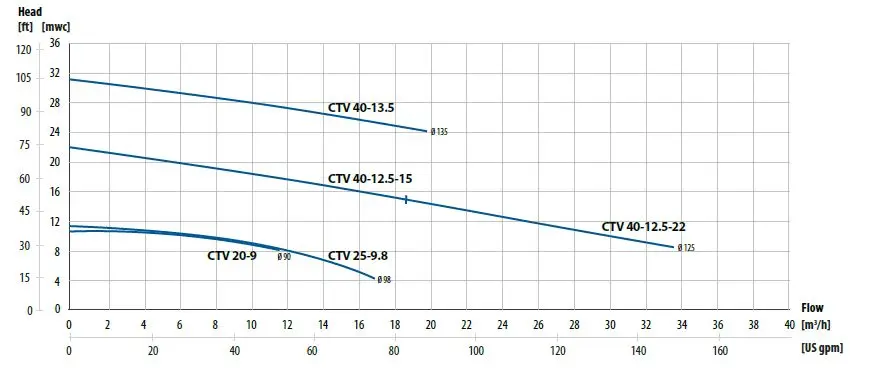

| CTV 20-9 stainless steel | 12 | 0.55 | ¼” |

| CTV 25-9.8 stainless steel | 11 | 0.75 | 1” |

| CTV 40-12.5 stainless steel | 19 | 1.5 | 1½” |

| CTV 40-13.5 stainless steel | 20 | 2.2 | 1½” |

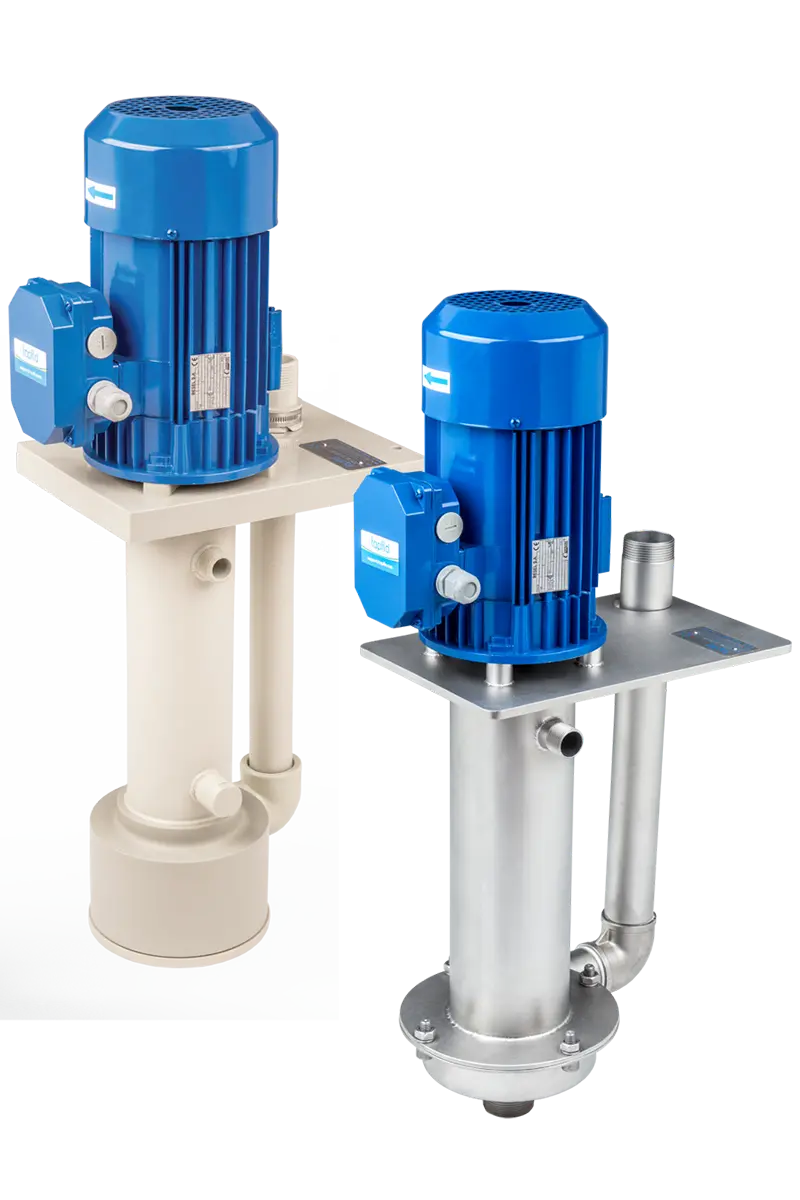

CTV is a single stage vertical centrifugal pump that is simple but very reliable in duty.

It is manufactured from:

- plastic (PP or PVDF)

- stainless steel (AISI 316L).

The pump is specialized for transfer and circulation of various liquids from containers, sumps and tanks.

Features & Benefits

- Leakage free and dry running safe

CTV is installed vertically with the motor above the liquid surface. In this way the pump does not need any mechanical seal that usually is a source for leakage problems. Furthermore the pump is designed to be dry running safe. - Maintenance free

The simple design without bearings or mechanical seals grants for a pump that is usually maintenance free. CTV is also insensitive of solids, particles up to Ø 6 mm are allowed. - Replacing self priming pumps

In many installations the CTV pump replaces a self-priming pump. The CTV pump head is submersed in the liquid. The pump operates more reliably compared to a self-priming pump. The submersion depth is up to 425mm (depending on model), but may also be equipped with a suction extension.

Typical APPLICATIONS

- Surface treatment: transfer and return pumping in galvanizing, hot zinc, pickling and oxidation processes

- Water treatment: transfer and return pumping

- Heat exchangers: return pumping in heat exchangers

- Waste disposal: emptying sumps