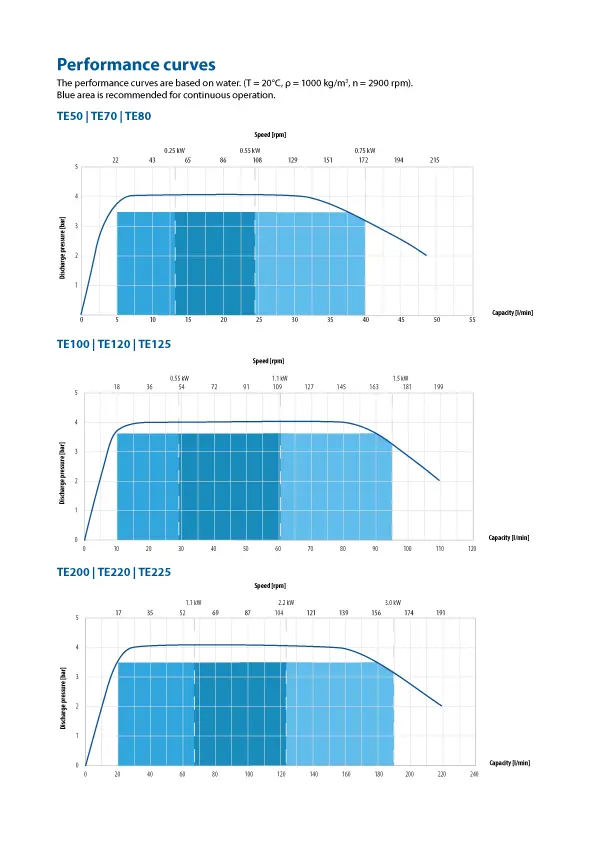

Technical data

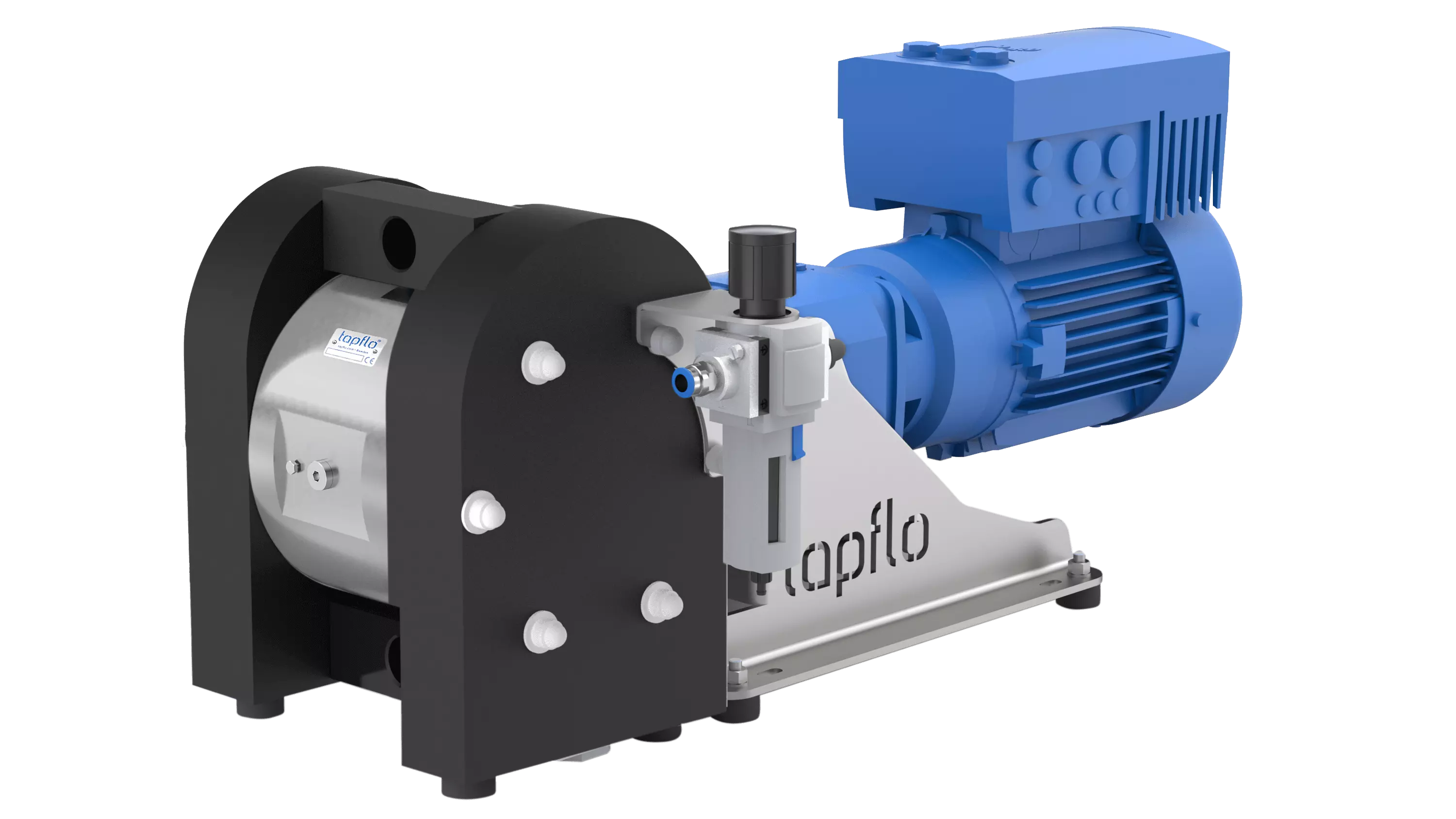

| PE & PTFE | Max capacity (l/min) |

Connections BSP inv. |

| TE50P | 48 | 1/2" |

| TE100P | 110 | 1" |

| TE200P | 220 | 1 1/2" |

| TE50T | 48 | 1/2" |

| TE100T | 110 | 1" |

| TE200T | 220 | 1 1/2" |

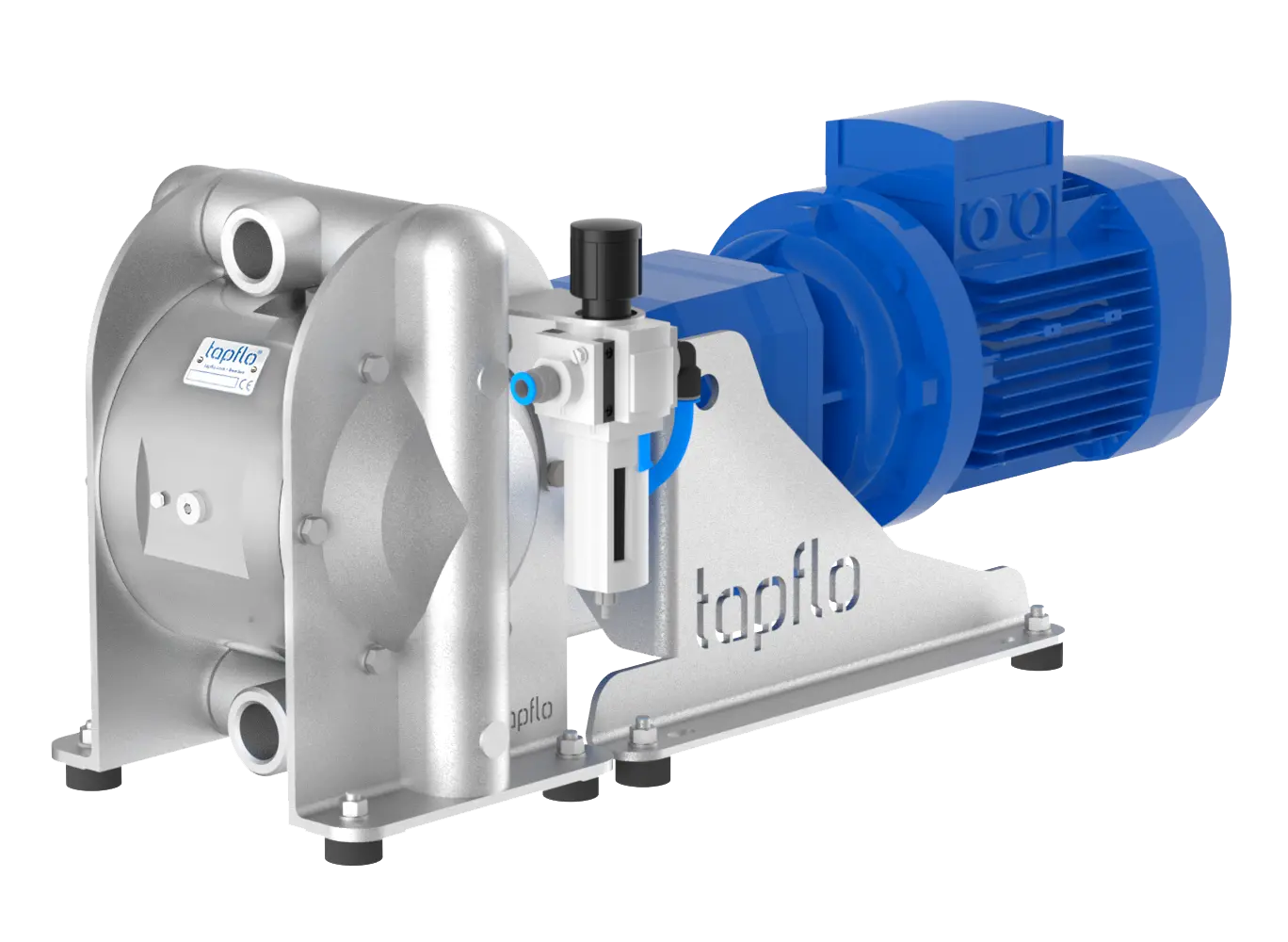

| Metal | Max capacity (l/min) |

Connections BSP inv. |

| TE70S | 48 | 3/4" |

| TE120S | 110 | 1" |

| TE220S | 220 | 1 1/2" |

| TE70A/C | 48 | 3/4" |

| TE120A/C | 110 | 1" |

| TE220A/C | 220 | 1 1/2" |

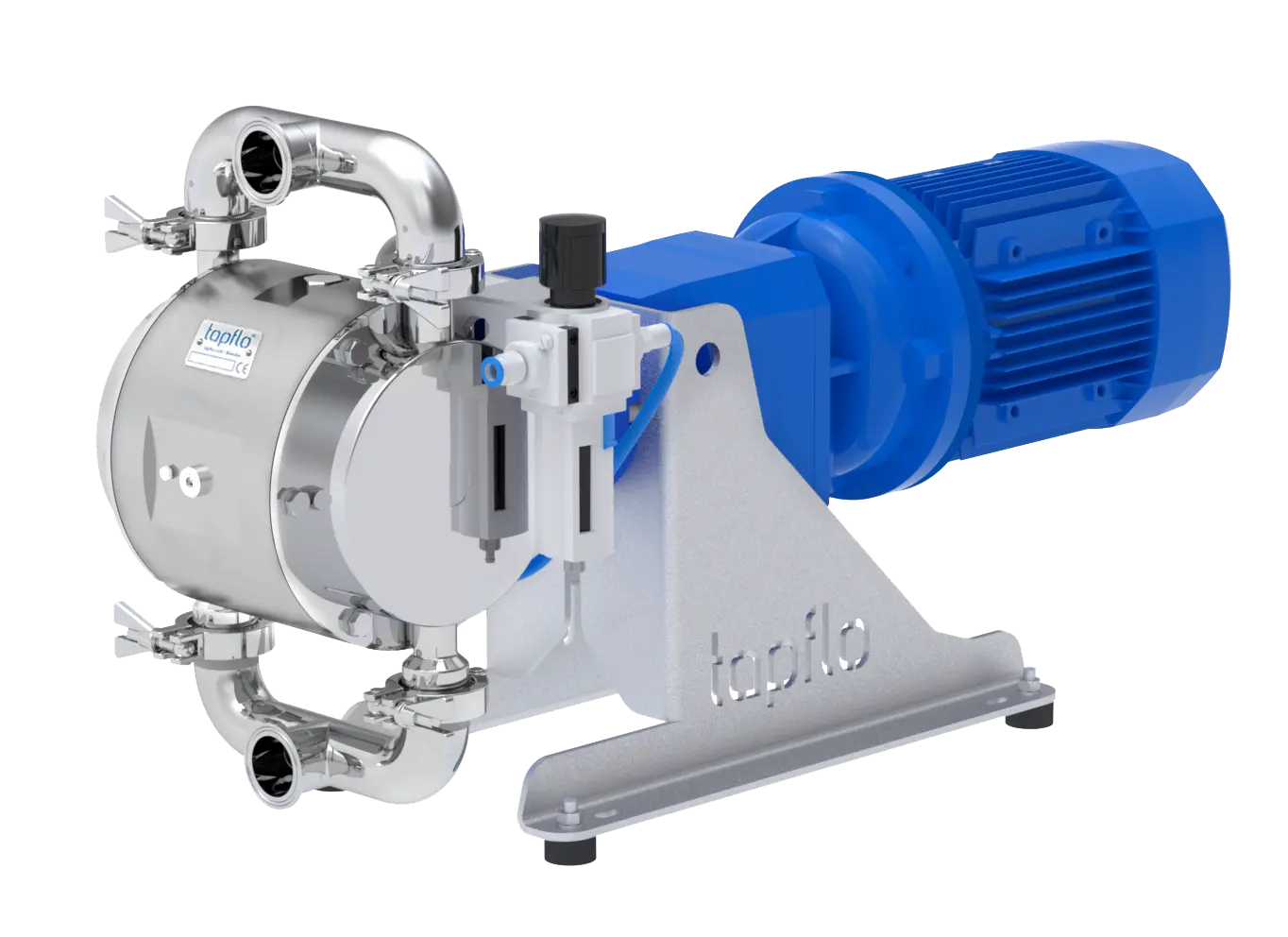

| Sanitary | Max capacity (l/min) |

Connections standard |

| TE80 | 48 | DN 25 SMS 3017 tri-clamp |

| TE125 | 110 | DN 38 SMS 3017 tri-clamp |

| TE225 | 220 | DN 51 SMS 3017 tri-clamp |

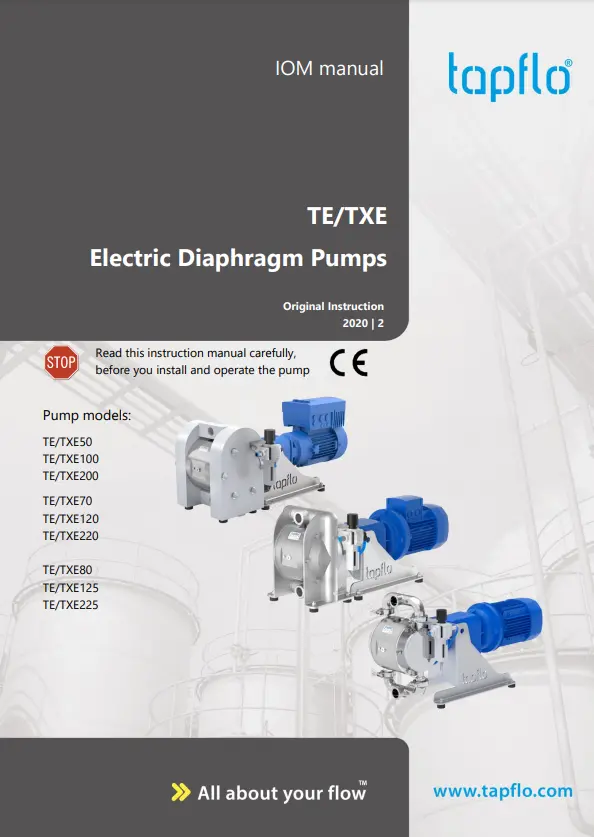

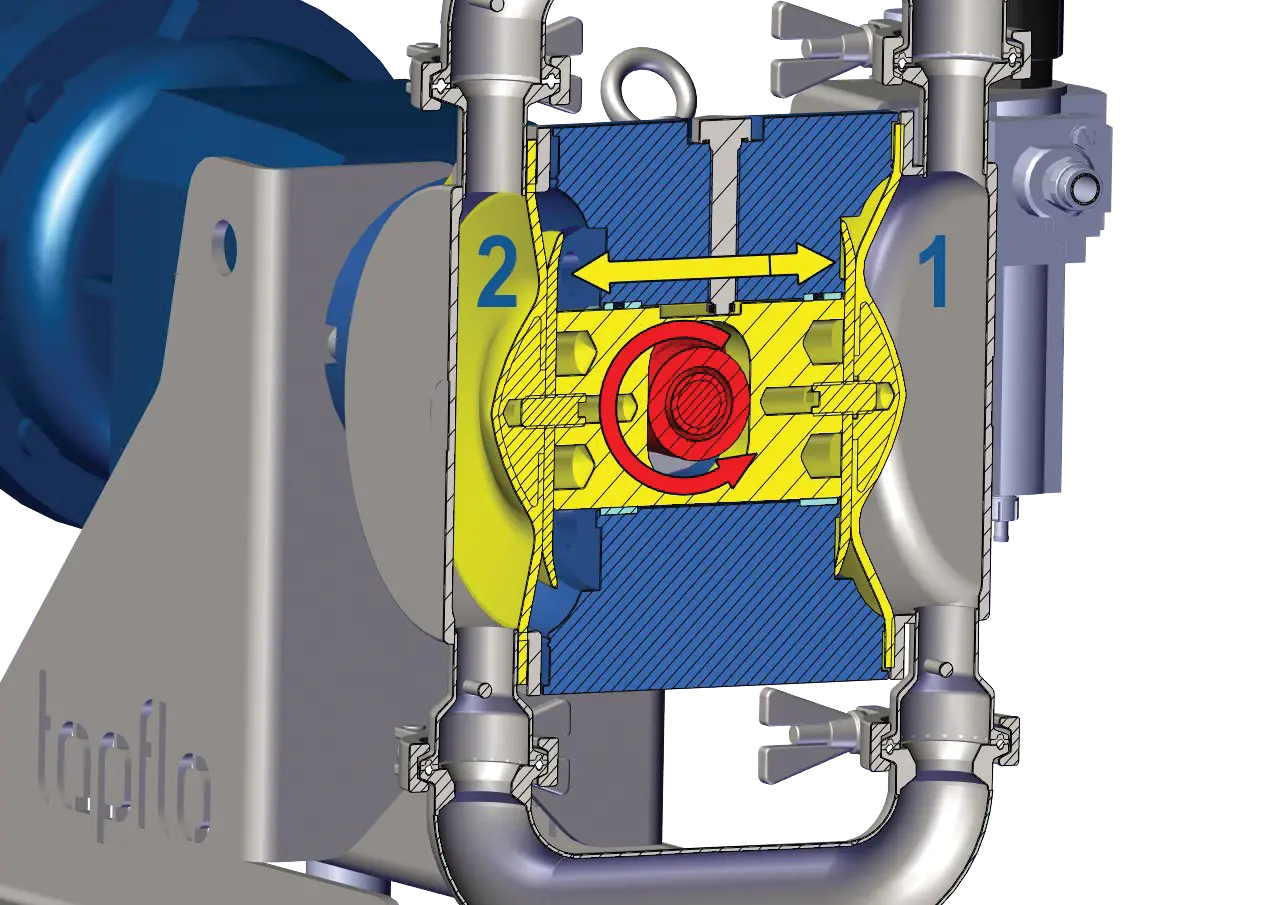

The Tapflo EODD pump series gently pumps the most aggressive media, is self-priming and sealless. Electric double diaphragm pumps withstand abrasive particles and even dry running.

Materials of wetted parts: Aluminium, PTFE coated aluminium, Stainless steel (industrial and hygienic), Plastic (PE & PTFE)

Diaphragm and ball materials: PTFE, TFM modified PTFE, EPDM, NBR, FKM Up to 220 l/min Up to 4 bar

Options: Pressure switch, Built-on frequency inverter.

Typical applications

- Chemical industry

- Surface conditioning

- Water treatment

- Paint, print industry

- Pulp and paper industry

- Hygienic applications

- Mechanical industry

- Varnish industry

Features & Benefits

- Low energy cost. Electricity cost < compressed air cost, high efficient (IE3 class) drive

- Long diaphragm lifetime. Pneumatic and mechanical support of the diaphragm

- Run dry without damage. Easy to use, no need of guarding device

- Low spare parts cost. Electric Diaphragm pump has an almost identical design of the wetted side as the standard Tapflo air operated diaphragm pump, therefore many spare parts are the same

- Self-priming from dry suction pipe. More options of installation

- Clean & easy maintenance. No hydraulic fluid required, no danger of leakage

- Few components & long life design. Low downtime and maintenance cost